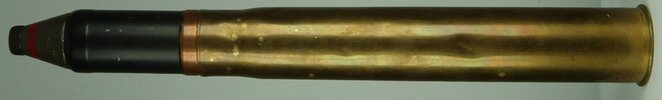

Cutaway models of two WW2 Russian 45 x 310R shells for the M1932 anti tank gun and universal gun.

This shell type was put to use in the 1930’s for use in the M1930 tank gun for the T-24 tank but it was mainly used in the M1932 and M1937 anti tank gun. The Germans captured large numbers of these guns and called them 4,5cm Pak 184(r)

This type of gun was also used in the M1932 guns on the A-20 the T-26 and the T100 tanks , called the Kwk 194/5(r) by the Germans.

Two types of primers were available for the shellcase, a firing pin primed percussion primer for the M1932 gun and an electrically primed type for the tank guns. Therefore, tank gun and gun type shells are not interchangable.

Top of the picture:

The UBRZ-243 APHE-T (Armour Piercing High Explosive –Tracer) shell. A Steel projectile with a flat, hardened nose and a ballistic cap. A hole has been drilled in the base that contains 19 grams of explosive filler and a MD-5 base fuze. A 1mm thick lead gasket is placed between body and fuze.

The shellcase is brass made and contains 360 grams of powder. This cartridge has a percussion primer and is therefore gun use only. Note the cartboard spacer that holds the powdercharge in it’s lower position.

Projectile weight : 1,43 kg

Vo : 820 mtrs/se

Penetration : 31 mm at 500 mtrs at a 60 degrees angle

The fuze MD-5:

A steel made one piece fuze with an aluminium tracer capsule screwed to the base. A long , aluminium detonator is screwed in the top of the fuze.

The inner parts of the fuze are made up ot three parts ; the firing cap housing with the firing cap and a lead weight ring at the base (4), an interupted set back sleeve with a weakening groove (5), and the firing pin with integrated flash hole.

Functioning of the fuze:

On firing, the interupted sleeve is set back , bending open over the longitudal weakening groove to move down over the wider part of the firing cap housing. The firing cap housing is now free to move forward into the firing pin on impact. The flame of the firing cap moves through the flashole into the detonator, exploding the projectile.

Bottom of the picture:

The UO-243 High explosive shell, fuzed with a KTM-1 fuze. This projectile is a long , mild steel fragmentation body, filled with 118 grams of TNT . It falls deep into the shellcase and therefore has the red copper drivingband high up the projectile body. The shellcase is brass made and contains 115 grams of powder. This cartridge has a percussion primer and is therefore gun use only. Note the cartboard spacer that holds the powdercharge in it’s lower position.

Projectile weight : 2,15 kg

Vo : 343 mtrs/sec

The fuze KTM-1:

The KTM-1 fuze is a two piece steel made fuze. The upper housing part contains the firing pin and a brass lip spring . The lower part contains the safety mechanism, the firing cap and the booster.

Functioning of the fuze:

In rest, the firing cap (1) is held in backward position by a four lips brass stirrup spring (2). The stirrup spring is surrounded by a set back sleeve (3), held in upward position by the stirrup spring lips and a spring surrounding the set back sleeve. The lower part of the firing cap is plug shaped and plugs of the hole to the detonator, housed in the booster. A red copper ringshaped gasket is crimped around the base of the firing cap. This is done to prevent accidental explosion on transport of the ammunition and firing of the gun.(on firing the gun, the firing pin sets back, just not able to hit the firing cap)

On firing, the set back sleeve moves down, bending the lips inward , untill they fall into the chanber in the sleeve (3*). After acceleration has stopped, and the speed is constant, the spring surrounding the sleeve pushes the sleeve upward. As the lips of the stirrup spring are locked up in the chamber of the sleeve, the firing cap moves forward with the sleeve (also opening the hole to the detonator). This enables the firing pin to hit the firing cap on impact, or -on low impact angeles- when the firing cap moves forward into the firing pin (the length of the chamber in the sleeve allows the firing cap to move further upward). The flame of the firing cap will travel into the detonator, exploding the booster and the main charge.

Regards, DJH

This shell type was put to use in the 1930’s for use in the M1930 tank gun for the T-24 tank but it was mainly used in the M1932 and M1937 anti tank gun. The Germans captured large numbers of these guns and called them 4,5cm Pak 184(r)

This type of gun was also used in the M1932 guns on the A-20 the T-26 and the T100 tanks , called the Kwk 194/5(r) by the Germans.

Two types of primers were available for the shellcase, a firing pin primed percussion primer for the M1932 gun and an electrically primed type for the tank guns. Therefore, tank gun and gun type shells are not interchangable.

Top of the picture:

The UBRZ-243 APHE-T (Armour Piercing High Explosive –Tracer) shell. A Steel projectile with a flat, hardened nose and a ballistic cap. A hole has been drilled in the base that contains 19 grams of explosive filler and a MD-5 base fuze. A 1mm thick lead gasket is placed between body and fuze.

The shellcase is brass made and contains 360 grams of powder. This cartridge has a percussion primer and is therefore gun use only. Note the cartboard spacer that holds the powdercharge in it’s lower position.

Projectile weight : 1,43 kg

Vo : 820 mtrs/se

Penetration : 31 mm at 500 mtrs at a 60 degrees angle

The fuze MD-5:

A steel made one piece fuze with an aluminium tracer capsule screwed to the base. A long , aluminium detonator is screwed in the top of the fuze.

The inner parts of the fuze are made up ot three parts ; the firing cap housing with the firing cap and a lead weight ring at the base (4), an interupted set back sleeve with a weakening groove (5), and the firing pin with integrated flash hole.

Functioning of the fuze:

On firing, the interupted sleeve is set back , bending open over the longitudal weakening groove to move down over the wider part of the firing cap housing. The firing cap housing is now free to move forward into the firing pin on impact. The flame of the firing cap moves through the flashole into the detonator, exploding the projectile.

Bottom of the picture:

The UO-243 High explosive shell, fuzed with a KTM-1 fuze. This projectile is a long , mild steel fragmentation body, filled with 118 grams of TNT . It falls deep into the shellcase and therefore has the red copper drivingband high up the projectile body. The shellcase is brass made and contains 115 grams of powder. This cartridge has a percussion primer and is therefore gun use only. Note the cartboard spacer that holds the powdercharge in it’s lower position.

Projectile weight : 2,15 kg

Vo : 343 mtrs/sec

The fuze KTM-1:

The KTM-1 fuze is a two piece steel made fuze. The upper housing part contains the firing pin and a brass lip spring . The lower part contains the safety mechanism, the firing cap and the booster.

Functioning of the fuze:

In rest, the firing cap (1) is held in backward position by a four lips brass stirrup spring (2). The stirrup spring is surrounded by a set back sleeve (3), held in upward position by the stirrup spring lips and a spring surrounding the set back sleeve. The lower part of the firing cap is plug shaped and plugs of the hole to the detonator, housed in the booster. A red copper ringshaped gasket is crimped around the base of the firing cap. This is done to prevent accidental explosion on transport of the ammunition and firing of the gun.(on firing the gun, the firing pin sets back, just not able to hit the firing cap)

On firing, the set back sleeve moves down, bending the lips inward , untill they fall into the chanber in the sleeve (3*). After acceleration has stopped, and the speed is constant, the spring surrounding the sleeve pushes the sleeve upward. As the lips of the stirrup spring are locked up in the chamber of the sleeve, the firing cap moves forward with the sleeve (also opening the hole to the detonator). This enables the firing pin to hit the firing cap on impact, or -on low impact angeles- when the firing cap moves forward into the firing pin (the length of the chamber in the sleeve allows the firing cap to move further upward). The flame of the firing cap will travel into the detonator, exploding the booster and the main charge.

Regards, DJH

Attachments

-

01 - 45mm UO-243 HE and UBRZ 243 APHE cartridges.JPG98.2 KB · Views: 36

01 - 45mm UO-243 HE and UBRZ 243 APHE cartridges.JPG98.2 KB · Views: 36 -

02 - 45mm UO-243 HE and UBRZ 243 APHE projectiles.JPG121.6 KB · Views: 35

02 - 45mm UO-243 HE and UBRZ 243 APHE projectiles.JPG121.6 KB · Views: 35 -

04 - arming mechanism MD-5 fuze of UBRZ-243 APHE shell.JPG23.7 KB · Views: 30

04 - arming mechanism MD-5 fuze of UBRZ-243 APHE shell.JPG23.7 KB · Views: 30 -

05 - arming mechanism KTM-1 fuze of UO-243 HE shell.JPG81.9 KB · Views: 27

05 - arming mechanism KTM-1 fuze of UO-243 HE shell.JPG81.9 KB · Views: 27 -

06 - UBRZ 243 APHE cartridge backside.JPG74.2 KB · Views: 24

06 - UBRZ 243 APHE cartridge backside.JPG74.2 KB · Views: 24 -

07 - 45mm UO-243 HE cartridge backside.JPG73.2 KB · Views: 29

07 - 45mm UO-243 HE cartridge backside.JPG73.2 KB · Views: 29 -

01B - 45mm UO-243 HE and UBRZ 243 APHE cartridges.JPG235.3 KB · Views: 27

01B - 45mm UO-243 HE and UBRZ 243 APHE cartridges.JPG235.3 KB · Views: 27 -

03 - 45mm M1932_gun.jpg335.2 KB · Views: 22

03 - 45mm M1932_gun.jpg335.2 KB · Views: 22