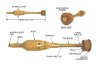

Here is a Chinese 82mm projectile I need information about. Possibly a practice/smoke? for a smooth-bore recoilless gun.

The top part is a modified 82mm mortar with 6 holes tapering out from 8mm to 12mm at the top.

If the tail stem is unscrewed you can pull it from the mortar body.It is held by 4 spring-loaded ball bearings. The plastic disc, ring and tail can rotate in the mortar tail.

Body is impressed: 11 - 83 - 9103. Black print: 82 (2 characters) 4 - 86 - 71. Tail stamped: 9 - 85 - 9103.

Body is 82mm diameter. 500mm overall length. Weight 3.42kg. I guess it has a charge or casing attached to the ring? All info is welcome.

The top part is a modified 82mm mortar with 6 holes tapering out from 8mm to 12mm at the top.

If the tail stem is unscrewed you can pull it from the mortar body.It is held by 4 spring-loaded ball bearings. The plastic disc, ring and tail can rotate in the mortar tail.

Body is impressed: 11 - 83 - 9103. Black print: 82 (2 characters) 4 - 86 - 71. Tail stamped: 9 - 85 - 9103.

Body is 82mm diameter. 500mm overall length. Weight 3.42kg. I guess it has a charge or casing attached to the ring? All info is welcome.