microplastic

Well-Known Member

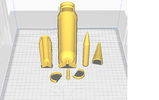

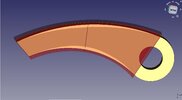

made with a 3d printer: cutaway model of a 30mm x173 PGU-14/B Armour Piercing Incendiary round used by GAU-8 on A-10. The PGU-14/B round has a lightweight body which contains a sub-calibre high density penetrator of Depleted Uranium (DU). In addition to its penetrating capability DU is a natural pyrophoric material which enhances the incendiary effects.

interessting way to make cutaway models...

interessting way to make cutaway models...