Hi all,

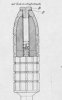

please have a look at the attached photo. Its the lower left corner of an otherwise unhelpful German WW1 photo which shows a type of grenade which I just cannot identify. The grenades are fairly small, hand grenade size and look a bit - in my opinion - like 1917n/a with extras above the midline fragmentation ring.

I posted this a while back in a FB group which deals with grenades but they also drew a blank other than it could be „nose caps for mortar rounds“. But no such mortar round is known to me (German, WW1).

That is unfortunately already all that I can attribute here as I do not have any further info. Who has an idea what type of grenade can be seen on the photo?

Thanks a lot!

please have a look at the attached photo. Its the lower left corner of an otherwise unhelpful German WW1 photo which shows a type of grenade which I just cannot identify. The grenades are fairly small, hand grenade size and look a bit - in my opinion - like 1917n/a with extras above the midline fragmentation ring.

I posted this a while back in a FB group which deals with grenades but they also drew a blank other than it could be „nose caps for mortar rounds“. But no such mortar round is known to me (German, WW1).

That is unfortunately already all that I can attribute here as I do not have any further info. Who has an idea what type of grenade can be seen on the photo?

Thanks a lot!