British Ordnance Collectors Network

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

WWI - Munitions Machinery Adverts

- Thread starter TimG

- Start date

This one is also very nice. It's a tool for a graduating machine used to make the No.80 fuze scales. This machine in the following picture is from the Scovill Mfg. Co., Waterbury, Conn. In the picture the tool ring is the left one and the right is the time ring of the fuze (No.85 PTTF)

Attachments

Last edited:

one more real life picture (fixing the driving band):

Attachments

another one (Winslow Brothers Co., Chicago):

Attachments

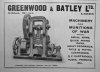

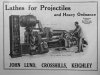

Yes, I like the fact that the open herringbone gearing is right next to the forward/reverse selector lever, 1 slip & you are mince meat!

"Illustration shows machine with gear guards removed"

Such large lathes rotated very slowly, so no googles were required. Tungsten carbide cutting plates allowing high cutting speeds were not invented at this time. But with simple hardened steel + flood cooling + low r.p.m. and a large cutting depth they still were able to produce thousands of shells per week like we wouldn't be able to do today with our degraded industry. When China stops deliveries we wouldn't even have electrical light in our factories

In my opinion work safety was still present in this era and not that bad as some may think. But course not that overdone as sometimes today.

Last edited:

one more real life picture (fixing the driving band):

Note the lake of hydraulic oil beneath the tool! There was no Environment Agency or HSE to oversee conditions in those days.

Considering the size of the cylinders, it probably functioned under a lower pressure than one might think.

Thanks to all for these wonderful pictures!!!!!!

Possibly the big brother of the lathe in the advertisement. Picture from the Bethlehem Steel Co: lathe for turning steel ingots for gun barrels. It has the same sweet little motor and the Citroen gears:

Attachments

Makes you wonder what happened to all the machinery, lathes, pillar drills, etc, after the end of the great war. Scrapped or sold off to other countries looking to boost their military output? Possibly adapted to produce non military components? Truly wonderful machines.

If only one could travel back in time. With a huge crane and a big lorry.

And a more tolerant wife...

If only one could travel back in time. With a huge crane and a big lorry.

And a more tolerant wife...