Dave83

Well-Known Member

Hello

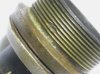

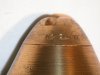

I have many fuzes of ww1 some of them needs to get cleaned up .

For better cleaning acces i want to dismantle the fuzes ,now my question does anyone know how to dismantle fuzes i mean not the technical side i mean the parts are corroded and very tuff to unscrew .

is there are a technique to get the parts losen ?

Has anyone experience to do this ?

thanks in advance

wbr David

I have many fuzes of ww1 some of them needs to get cleaned up .

For better cleaning acces i want to dismantle the fuzes ,now my question does anyone know how to dismantle fuzes i mean not the technical side i mean the parts are corroded and very tuff to unscrew .

is there are a technique to get the parts losen ?

Has anyone experience to do this ?

thanks in advance

wbr David