You removed the back plate and used a crowbar?

After cutting mine in two, I had a straight shot at the plaster. I used a dig bar for hours on both ends, causing my arms a two week recovery time. I am a very tenacious person who will jump into anything, no matter how hard the work is. I found strength and endurance I did not know I had removing that plaster.

It was 600 pounds of some tough stuff, in which I removed every last drop. I cannot imagine the difficulty you experienced, having to work through a 12 inch hole?

Your piece is very, very nice. I wish it could talk, even more so than mine.

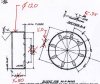

As you can see, my casings "as purchased" paint was similar to yours. Where did you find yours? Do you have a story? Mine just came off of a farm and was pulled out of it’s former resting place, waiting on me to pick it up.

Pulling the thing home on a trailer, my friend and I talked about what we would do if we got pulled over. If asked what we had, my friend replied "It is a boat anchor. They told us the get the heaviest thing we could find!"

Also, concerning the rings of primer on our casings; my 500 pound AN-M64 came with an original pair of those shipping pads/rings.