Hello,

Having decided to attempt to reband this nice German 7.7cm, I thought I'd keep a log of how it goes for those members who might be interested.

It's another one of those projects I've never undertaken before so may fall flat on its face....

Sadly, some of the original driving band had crumbled over time, and so I removed what was left to reveal a clean band recess.

The idea is to pour molten Pewter into a preformed cavity/mould made from Plaster of Paris, and to allow the molten metal to form a complete unbroken 'ring' within the shell driving band recess. Pewter seemed to be a good compromise; it has a low melting point, is cheap, and the colour when solid is not too dissimilar to Zinc Alloy.

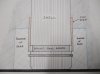

The pictures show the shell before the project. Further pictures show the shell base encased with PoP. A strip of 5mm thick floor lino was wrapped around the shell, covering the driving band recess, with the lower edge of the lino laying about a millimetre or two below the recess. This will allow a small margin for error when it comes to profiling the band at the lower edge. Better to have more material than less.

After the plaster had cured, the Lino strips were removed leaving an opening all around the shell into which the pewter will be poured. Fortunately, Plaster of Paris has a very low shrink rate, so no cracks have formed in the mould. The plaster recess around the shell is perfectly uniform at the lower edge of the shell driving band recess, and the plaster recess is larger to allow for a larger 'new' Driving band to be moulded. This can then be profiled to the correct size.

The pewter I'll use will be broken old English Pewter tankards.

The next stage is the melting and pouring of the pewter into the plaster recess.....Watch this space!

Cheers!

Last edited: