pzgr40

Well-Known Member

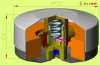

Cutaway model of an Anti Personel and Anti Tire mine. The mine is of Brittish origin and nicknamed "ointmentbox" by the Brittish troops.

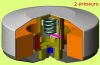

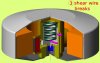

Diameter of the mine is 51mm, it's heigth is 28 mm. Weight of the mine is 142 gram, of which 57 grams TNT in the shape of a ring.

Functioning of the mine: The mine is placed in the ground or on a road. In rest, the lower cup, containing the firing cap housing with the firing cap is held apart from the upper cup by means of a shear wire through the firing pin and the firing cap housing. The shear wire fixates the firing pin. The flash holes of the detonator housing (2pcs at 180 each, painted white) are telescoped over the firing cap housing. In case of an misfire of the firing cap while in rest, the flash holes are in shut off position, and the mine will not explode. This is the only safety mechanism of the mine. When pressure is applied, the upper cup is pushed down over the lower cup, up to a moment where the upper cap pushes direct upon the firing pin, at the same moment tensioning the spring. At 10kg force, the shear wire breaks, releasing the firing pin into the firing cap (blue). While the mine is pressed in, the flash holes of the detonators are opened to receive the flame of the firing cap.

I've practiced a bit of Acad 3D again after a long time, see results below.

Regards DJH

Diameter of the mine is 51mm, it's heigth is 28 mm. Weight of the mine is 142 gram, of which 57 grams TNT in the shape of a ring.

Functioning of the mine: The mine is placed in the ground or on a road. In rest, the lower cup, containing the firing cap housing with the firing cap is held apart from the upper cup by means of a shear wire through the firing pin and the firing cap housing. The shear wire fixates the firing pin. The flash holes of the detonator housing (2pcs at 180 each, painted white) are telescoped over the firing cap housing. In case of an misfire of the firing cap while in rest, the flash holes are in shut off position, and the mine will not explode. This is the only safety mechanism of the mine. When pressure is applied, the upper cup is pushed down over the lower cup, up to a moment where the upper cap pushes direct upon the firing pin, at the same moment tensioning the spring. At 10kg force, the shear wire breaks, releasing the firing pin into the firing cap (blue). While the mine is pressed in, the flash holes of the detonators are opened to receive the flame of the firing cap.

I've practiced a bit of Acad 3D again after a long time, see results below.

Regards DJH