crunchysuperman

Member

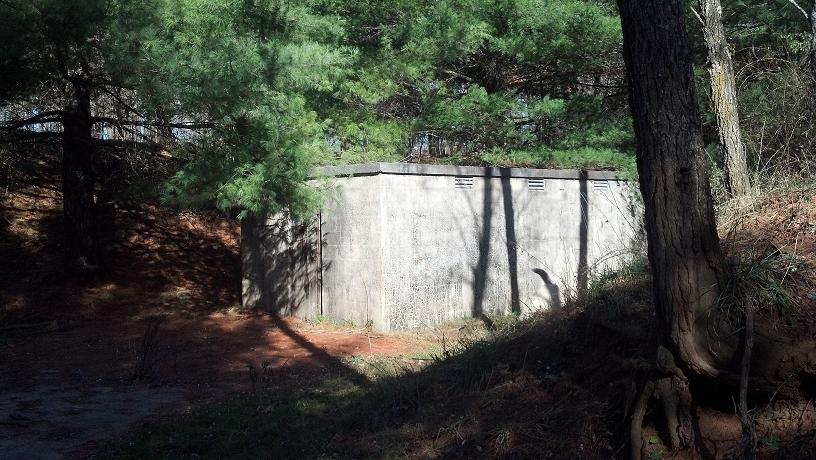

This building contains the production line and presses for the forward & aft propellant charges. It appears that this line was added later to what was originally a generic work building. You can see the front half of the building is comprised of huge concrete "cubicles" whose walls go up through the roof. The ceiling & back walls were flimsy so that if you blew up, the blast went up & backwards while not spreading to the station next to you. Many of the buildings were made this way. The plywood awning enclosure was added to house the conveyor that moved the pressed & dried charges to the back of the building for further assembly. The exhaust stacks were added and those workrooms were turned into drying rooms to oven-cure the charges. You can see at the far end of the building that the roof of two of the "cubicles" have been enclosed. Those are where the elevators to the press hoppers are.

This is the forward charge press. It's very difficult to get good pictures of these machines, as they take up every last inch of the stall where they were mounted.

This is the elevator that delivered the powder to the hopper at the top of the press (the reason for the extended roof in the outside pic of the building). Note the conveyor on the right that moved the finished charge down the line.

Control area for the charge press. You can see the machine through the glass a little bit. That glass is about 4 inches thick. Out of frame to the left is the control for the aft charge with a window looking through to a similar press room. Out of frame to my right is the conveyor moving all the finished charges down the line.

This is the forward charge press. It's very difficult to get good pictures of these machines, as they take up every last inch of the stall where they were mounted.

This is the elevator that delivered the powder to the hopper at the top of the press (the reason for the extended roof in the outside pic of the building). Note the conveyor on the right that moved the finished charge down the line.

Control area for the charge press. You can see the machine through the glass a little bit. That glass is about 4 inches thick. Out of frame to the left is the control for the aft charge with a window looking through to a similar press room. Out of frame to my right is the conveyor moving all the finished charges down the line.