Yes, so that the fuze is sealed and no moisture can get inside.

Not plastic, it is a thin paper disc.

So what's the difference between Emčz S/30 and mčz S/30 ?

The E variant is made of steel, the aluminium variant is sometimes called the A variant.

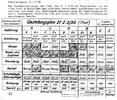

In the table below you can see the different drawing numbers in production.

Drawing number:

| Mu 40640a | 23. 8. 1949 | first 11 000 pcs |

| Mu 40660 | 24. 12. 1949 | Not produced „war production“ steel body |

| Mu 40671 | 25. 1. 1950 | Production of 1950-51 |

| Zm 514 | 5. 1. 1951 | variant E with steel body and cone |

| Zm 532 | 30. 5. 1952 | Production from 1952 to July 1954 |

| Zm 537 | 28. 1. 1953 | Parts list Zm 1067 for A variant

Parts list Zm 1187 for E variant |

First variant A, with body and head made of duraluminum and brass clockwork mechanism, was sometimes described as peace-time variant. Variant E had steel body and sheet steel head and was prepared for war production. Steel fuzes with aluminum clockworks of the older design exist, they come from rectification of war produced German fuzes.

Since 1952 (drawing Zm 532) the attachment of the head was changed. The nut was replaced by a friction spring. (fuze in rons post)) On December 23rd 1953 the initial lot 0/53 of the „simplified and advanced model E“ of the mčz S30 was tested. This was manufactured according to the drawing No. Zm 537, starting with lot 9/54. (microplastics fuze) There are only a few lots of A model fuzes after this time mentioned in the testing protocols. Important change of the new model was the release of the timing key. The trigger lever assembly was completely replaced by one of the wedges. From an EOD perspective the change of the needle activation is the most important change. The pre-tensioned spring used in all previous variants was replaced by arming lever. Its movement due to the centrifugal force is transferred by use of angled surfaces at movement of the needle (see the mčz S/30rp entry for details). Both A and E models had Dural clockworks.

Production:

Mechanical time fuzes were manufactured on the Czech teritory during WW2 in Nový Bor (Rachmann Metallwerke-cxl), Broumov (Junghans Uhrenfabrik-ksm) and Meziměstí u Broumova (Messap Halbstadt-ojo). After the end of war vast stocks of ZtZ S/30 fuzes of various models and manufacturers were gathered in army stores. It was decided that the fuzes will undergo so called rectification. The fuzes were sorted the clock mechanisms were dried and serviced, faulty parts changed. Krup-Thiel fuzes were rectified in Nový Bor (avm) and Junghans fuzes in Chronotechna Šternberg (cro).

First rectified lots (1-3/48) were received from Nový Bor in February of 1949. From 1948 to 1953 trophy fuzes of A, A1, B, B1, C, D, E, E kurz variants were rectified. A lot always consisted of single fuze variant. Spare parts were manufactured directly in Nový Bor or in Adamov. If new fuze bodies were used (made in Adamov), the fuzes were marked mčz S30 avm (E mčz S30 avm). Total number of rectified fuzes exceeded 600 000 pieces.

Since 1949 a new production of fuzes started in Adamovské strojírny Adamov (fut). First batches were recieved by the army in January 1950 with lot 1/50. Last lot manufactured in Adamov was 38/55. It was followed by the mčz S/30rp production. Some of the lot numbers of rectified and newly produced fuzes overlap. For example in 1951 there are lots 1 to 20 of rectified fuzes and 1 to 25 of new fuzes. They can be distinguished in documentation by the factory code in the marking. The mčz S/30 fut for new fuzes and mčz S30 avm for rectified.

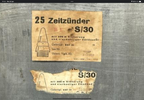

Markings

The fuze markings changed in time. First the German designation ZtZ S/30 was used also for the new manufacture of 1950. Fuzes produced in 1951 bear the designation S30. Steel bodied fuzes of 1952 have again the designation ZtZ S30. In 1952 the markings changed again to MČZ S30 and a year later to mčz S30. When steel was used for the material of the body the markings were E mčz S30. In documentation the designation mčz S30KT appears to distinguish the Krupp clockwork fuzes from the Junghans system. Rectified fuzes with original body have crossed old manufacturing data and new lot number, year and manufacturers code. If a new body was used it was marked ZtZ even when the mčz designation was used for new fuzes.

The way of securing the cap cannot be used for identification if pre-cocked needle is used. The lot number is the only marker.

The text above is considering manufacture for the Czechoslovak army. The export data are not available (to me).

Bob.