British Ordnance Collectors Network

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Shrapnel Fuse Identification

Jimmykoystix

Member

On a recent walk on Fleetwood beach I found the following items which I believe are parts from a shrapnel shell circa 1880’s. The 2 larger brass parts have RL marking which I think indicates Royal Laboratory Woolwich. I also believe the markings 10/90 and 3/81 are the dates when either the part was made or recalibrated, can anybody confirm this or not. Plus what are the parts. The shrapnel ball is 25g and is metric 16.7mm diameter. I believe the 2 larger brass parts are part of the timing fuse used for artillery shells, but I’m not sure of this. Can anybody confirm what’s these parts are and were they all part of the same shell. Plus on a safety note is the timing fuse still armed?

Jimmykoystix

Member

Thanks for that, so it’s definitely part of a percussion fuze and not a timer?. Plus have got got any further info. on the percussion fuze eg drawings or manual?The first (RL II) is : fuze percussion Royal Laboratory Plain Mark II (N° 7)

No idea for the second (larger piece). Something like gaine adapter.

Royal Laboratory Mark II 1883

Hi All My latest acquisition a 'Royal Laboratory’s II percussion fuze' dated June 1883. apart from the images below that's all I know about the fuze, if anyone could provide any further documentation or information about this fuze it would be greatly appreciated.

www.bocn.co.uk

wingsofwrath

Well-Known Member

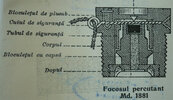

This exact percussion fuze was also used by Romania for our Armstrong 63mm (2.5-in) Model 1883 mountain guns. It was known as "Percussion Fuze model 1881".

It's interesting to note that there are a few differences between the British RL II, the m.1881 as it appears in the manual and ground-dug versions, namely the RL fuze has a big square cutout, the Romanian manual version has a big round cutout, whereas the ground-dug version dispenses with the cutout altogether and has a small plug over the hole through which the firing pin has been inserted into the body of the fuze.

It's interesting to note that there are a few differences between the British RL II, the m.1881 as it appears in the manual and ground-dug versions, namely the RL fuze has a big square cutout, the Romanian manual version has a big round cutout, whereas the ground-dug version dispenses with the cutout altogether and has a small plug over the hole through which the firing pin has been inserted into the body of the fuze.

Attachments

-

RL_Percussion_Fuze_Diagrams_1877.jpg183.9 KB · Views: 66

RL_Percussion_Fuze_Diagrams_1877.jpg183.9 KB · Views: 66 -

Focos percutie 63mm_m1881_1000.jpg537.8 KB · Views: 70

Focos percutie 63mm_m1881_1000.jpg537.8 KB · Views: 70 -

135463585_451647609193887_2037075185628335370_n.jpg684 KB · Views: 64

135463585_451647609193887_2037075185628335370_n.jpg684 KB · Views: 64 -

136946623_217600136777751_5316023012581610338_n.jpg300.3 KB · Views: 57

136946623_217600136777751_5316023012581610338_n.jpg300.3 KB · Views: 57 -

136729125_447726786595871_6562366024696233667_n.jpg599.6 KB · Views: 63

136729125_447726786595871_6562366024696233667_n.jpg599.6 KB · Views: 63

Last edited:

The dug fuze that you show looks more like the Armstrong Bolt percussion fuze on the british fuze list as No 1This exact percussion fuze was also used by Romania for our Armstrong 63mm (2.5-in) Model 1883 mountain guns. It was known as "Percussion Fuze model 1881".

It's interesting to note that there are a few differences between the British RL II, the m.1881 as it appears in the manual and ground-dug versions, namely the RL fuze has a big square cutout, the Romanian manual version has a big round cutout, whereas the ground-dug version dispenses with the cutout altogether and has a small plug over the hole through which the firing pin has been inserted into the body of the fuze.

Should just have one small hole in side of head for the fuze key, pin to engage in.The dug fuze that you show looks more like the Armstrong Bolt percussion fuze on the british fuze list as No 1

Bottom left on this page is a bronze stud from an RML projectile, has the date of shell manufacture on it. Projectile loaded from muzzle; studs engage three or more deep rifling grooves in barrel.

wingsofwrath

Well-Known Member

Do you have any pictures of the Armstrong Bolt Percussion fuze?The dug fuze that you show looks more like the Armstrong Bolt percussion fuze on the british fuze list as No 1

All I could find is a cutaway, which suggests that the internal arrangement on an Armstrong is different than that of the RL Mk.II.

What we have is, internally, definitely the latter, just without the square hole in the top that the British version has.

The way the hole is drawn in the Romanian manual might suggest ours had a round hole intially, but all the ones we've ever found have no hole at all, so it might be that's an error which slipped in when someone dupicated the original Armstrong drawing for the manual and assumed the hole on top must be round, because he's never seen the actual fuze, just the drawing he was copying.

Speaking of which, I assume the only reason to have it is to tighten the fuze down onto the shell and I have no idea how we did it. I mean, there is a small cylindical hole opposite the big one through which the safety wire is inserted so I'm assuming we used a "J" wrench, but I have no definite proof that is the case.

And the fact we have a fuze lacking the hole and a date of 1884 would suggest that is a modification made by Armstrong themselves and not somethign we did later in Romania.

Last edited:

Are we talking about the fuze shown above, a very green looking fuze and another photo looking down onto its top, then if we are, I am 99 percent sure that fuze is a British made Number 1 Bolt Percussion fuze, on its top I can read and see the metal stamp EOC, Elswick Ordnance Co and a date of, 2nd month 1884. The big hole in its side, visible in picture is where the square sliding bolt is installed and its cover disc has been blown out, on top above that there are two small drillings, normally with cover discs, where drop pin and a split pin from memory are installed. the one above the bolt goes through the bolt and holds it until setback on firing, then the bolt can slide outward due to centrifugal force and arm the fuze in flight. These fuzes were screwed into the shell with a fuze key that has a small pin protruding from a curved arm, the pin fits into a small hole in the side of the fuze head and then using the extended arm the fuze is screwed home, the thread should also be a slight taper, known as the General Service Taper, that allowed the fuze to drop nearly half way into the well before it contacted threads and then only needing minimal winding to seat it down, faster than the same length of thread if it was parallel.This exact percussion fuze was also used by Romania for our Armstrong 63mm (2.5-in) Model 1883 mountain guns. It was known as "Percussion Fuze model 1881".

It's interesting to note that there are a few differences between the British RL II, the m.1881 as it appears in the manual and ground-dug versions, namely the RL fuze has a big square cutout, the Romanian manual version has a big round cutout, whereas the ground-dug version dispenses with the cutout altogether and has a small plug over the hole through which the firing pin has been inserted into the body of the fuze.

If you go to page 5, fuzes, the 2nd one up from the bottom of the page reads, Fuze Percussion, Bolt, No1 and tin. Have a look at that fuze and compare it with your green looking dug fuze. Then let me know your reply.Are we talking about the fuze shown above, a very green looking fuze and another photo looking down onto its top, then if we are, I am 99 percent sure that fuze is a British made Number 1 Bolt Percussion fuze, on its top I can read and see the metal stamp EOC, Elswick Ordnance Co and a date of, 2nd month 1884. The big hole in its side, visible in picture is where the square sliding bolt is installed and its cover disc has been blown out, on top above that there are two small drillings, normally with cover discs, where drop pin and a split pin from memory are installed. the one above the bolt goes through the bolt and holds it until setback on firing, then the bolt can slide outward due to centrifugal force and arm the fuze in flight. These fuzes were screwed into the shell with a fuze key that has a small pin protruding from a curved arm, the pin fits into a small hole in the side of the fuze head and then using the extended arm the fuze is screwed home, the thread should also be a slight taper, known as the General Service Taper, that allowed the fuze to drop nearly half way into the well before it contacted threads and then only needing minimal winding to seat it down, faster than the same length of thread if it was parallel.